I was feeling very over whelmed looking at this large heavy steel plate. Now that the keel and top plate are cut out, they are easily manageable. Two guys can move the keel about, and the top plate can be carried with both hands.

The cutting, machining and welding are beyond my capabilities. But give it to the professionals, and 6 minutes later, the laser beam has cut out a perfect, complex keel shape complete with drilled holes. A few more minutes and the top plate was done in a thinner material.

Yes, there is more than one keel. However, I have a new build buddy!!! Hull 113 is also building right here in southern California. We both stood around for 18 minutes while the large plate became keels. Hull 113 has access to the machines to bevel and taper the edges, so that is the next step/stop.

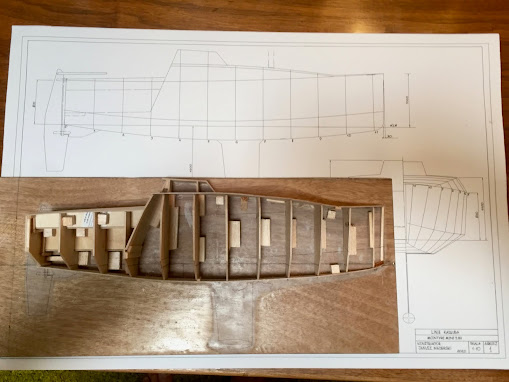

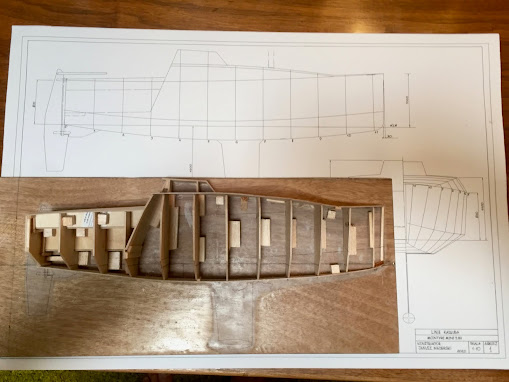

Meanwhile, I'm still waiting for the CNC kit to arrive, and looking for shop space. I did find time to epoxy glass the 1/20th model. Just like the real boat, there were wrinkles and amine blush to deal with. I also started a 1/20th half-full model that I will GIVE AWAY to one of you lucky blog readers. Stand by for details.

|

| Virgin steel plate |

|

| 5/8 (16mm) |

|

Laser Test Cut

|

|

| Cutting laser tattletale |

|

| Cut Keels |

|

| Cut Keels - excess removed |

|

| Top plates |

|

| Bad picture of the laser cutting |

|

| Top plates and keels off to get milled |

|

Model wrapped in epoxy and glass

| Beginning of half-hull

|

|